A pulverizer is a machine that is used for grinding various materials into a powdered form, and its application is significant in many industries. In other words, a pulverizer can also be referred to as a grinder.

The machine works using two major plates; the stationary plate, and a moving plate.

The plates work in counter direction with the aim of trapping particles in the adjustable gaps while using the compressive force to break them down.

Like jaw crushers, the plates rotating instead of oscillating motion and achieves a product with a somewhat thinner and smoother size range.

Worthy of note is the fact several companies are involved in the manufacture and supply of pulverizer machines

But for a high-quality pulverizer machine, those sourced from a reputable manufacturer will be the perfect pulverizer for your use.

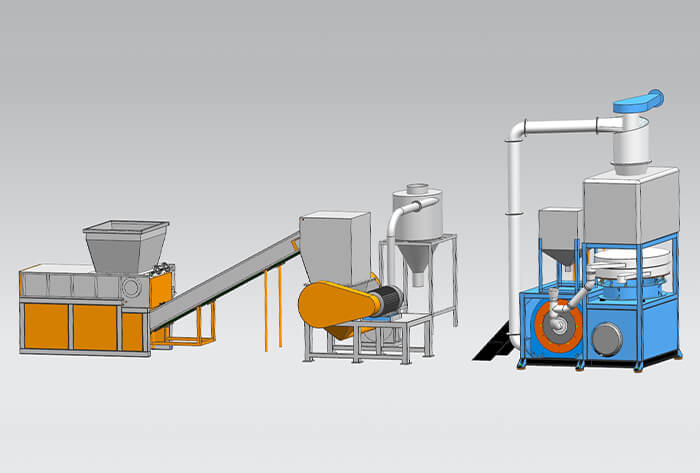

How The Plastic Pulverizer Works

The granular generator of plastics is one of the common processes used in the plastic recycling industries.

It is made up of an electric motor which rotates the rotor with the sharp cutting edges.

This rotor and motor with the blades are kept in a chamber that is closed where the plastics will be filled for granulation.

Depending on what you need, you can make a choice from the various sizes and shapes of chambers and the blade available.

With the help of the screen fixed in the chambers, the plastic particles can be sieved to obtain the desired size of granules you need.

Types Of Plastic Granulators

There are commonly two types of plastic granulators for you to choose from.

There is a type that is used mainly for engineering recycling waste, this type has a big granulator and it is expected to do higher work.

The second granulator is used in the recycling of plastic. These granulators have a relatively small size and are commonly used at home for small molding requirements.

Dangers Of Plastic Granulators

The machine is not meant to be children’s toys, and so care needs to be given when operating on them.

Ensure all machines are kept safe be they for home use or industrial purpose, and this will help reduce a lot of machine accident.

Granulators can be very dangerous if proper safety instructions are not followed as requested by the manufacturers.

What are the other pulverizer machines for making pieces of plastic?

There are two other types of machines used to granulate plastics.

ü Ring mill

It comprises of a huge rotating blade. There are minor holes under the edge in the cutting compartment.

After the blade slashes the plastic into the wanted mass, they drop off the holes.

ü Shredder

There is no dissimilarity from a granulator. They have even blades in this equipment that produce strips of plastic.

Occasionally, they also yield pieces that are squared shape when they labor both horizontally and vertically.

Conclusion

The pulverizer machines are used majorly granulating of plastics, it is one of the common process used in the plastic recycling industries.

There is a wide range of high-quality pulverizer machines available in the market to help you meet your several plastic recycling desires.

Though it could be challenging to get the best suppliers, it is important that you buy pulverizers machine from a reputable manufacturer to get top quality.

By continuing to use the site you agree to our privacy policy Terms and Conditions.