One of the main fields of SMW series pulverizer is to grind PVC waste in the recovery of pipes and profiles. The powder produced can be mixed with new PVC materials and re-entered into the extrusion production of pipes and profiles. This grinder can be selected with or without vibration sieve according to the customer's specific requirements for fineness.

The brand-new SMW series plastic pulverizer belongs to the turbo-type pulverizer series, which knife flywheel diameter from 500mm to 800mm. This pulverizer is high speed, turbo-type grinders for the processing of medium hard, impact resistant and friable materials,its mainly used in the field of rigid PVC recycling, such as the recycling of defective products of PVC pipes, profiles, plates and corner residual materials.

Working principle

In the airflow of high-speed rotation of the cutter head, the material is thrown toward the tooth plate due to the centrifugal force, and is crushed by the friction between the blade and the tooth plate. The fine powder is discharged with the air flow, and the coarse particles close to the tooth plate cannot be ruled out due to the obstruction of the baffle and continue to be crushed until the powder is discharged with wind.

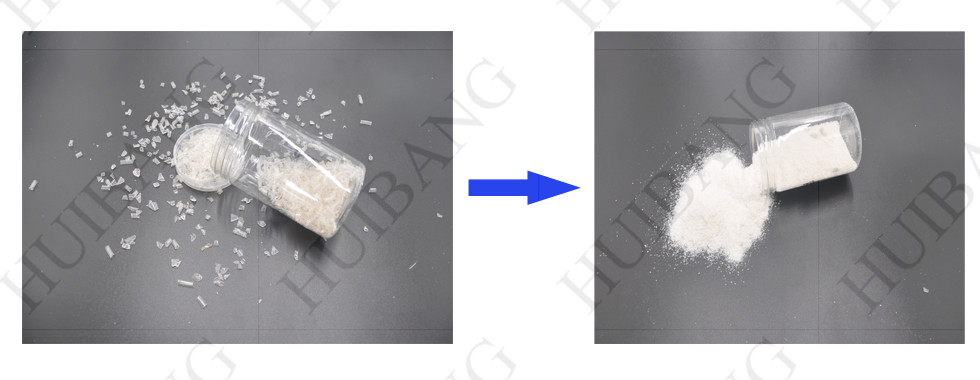

Grind samples (PVC)

1.Compared with similar grinders, its output is greatly improved (increased by 20%-50%) under the same power. It is energy-saving.

2.The dust collector is added to effectively reduce dust pollution.

3.The discharging of the main fan reduces labors intensity of operating workers.

4.The door cover of the host can be opened for convenience of maintenance and replacement of cutters.

5.Wind and water cooling system are adopted to decrease the working temperature inside the machine body, so the grinded material uneasy for denaturalization .

6.The powder mesh is adjustable (20-100 mesh).

Simple adjustment of cutting gap

Economical and effective

Easy to repair and replace parts

Low power consumption and high output

Model | SMW-500 | SMW-600 | SMW-800 |

Diameter of disc (mm) | ¢ 483 ±1 | ¢583 ±1 | ¢783 ±1 |

Rotary blade (pc) | 24 | 28 | 36 |

Static blade (pc) | 12 | 14 | 6 |

Main motor powder (kw) | 37 | 45/55 | 75/110 |

Capacity (kg/h) | 200-300 | 300-400 | 500-1000 |

By continuing to use the site you agree to our privacy policy Terms and Conditions.