When deliberating on high-quality pulverizer machines, take a look at the plastic pulverizer machine.

The plastic pulverizer is a piece of magnificent equipment used in crushing plastic into small and tiny sizes.

Former plastic pulverizers are highly difficult and complex and the results it produced are inaccurate sometimes.

To solve this problem customized powder pulverizer machines are introduced, and they generate colorful masterbatch.

All thanks to the manufacturer of the high-quality pulverizer. With this machine, you have the chance to achieve standard quality and colorful powder used in the manufacturing and compounding of masterbatch.

Also, the plastic pulverizer machines give the perfect and equal size of particles which ensures an adequate blending and mixing of additives.

Furthermore, plastic compounds such as Polycarbonate (PC), Polyamide (PA), and Polyethylene terephthalate (PET) are processed in an ambient heat through this processor.

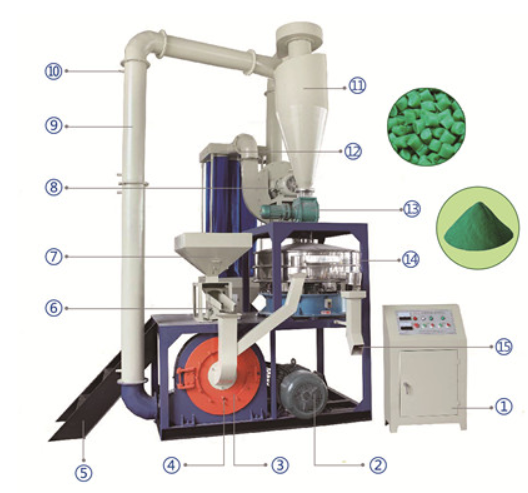

Once this is ongoing, the downstream fan will transfer the end product into a cyclone from the disc mill.

One notable thing is that this whole process is totally mechanical but the control cabinet will maintain and regulate all the activities.

However, for advanced and latest high-quality pulverizer to smash your plastic materials, buy PVC pulverizer from a reliable manufacturer.

Obviously, this is the most recommended option for your best processing services.

Materials That Can Be Ground Using Plastic Pulverizer Machine

PVC pulverizer machine can be used to grind many items such as buckets, bottles, pipes, and jugs.

After grinding, these materials are converted into granules which are afterward ready to be remolded into different other products.

A plastic granulator is normally large which allows it to grind much plastic at once.

More so, you can also buy PVC pulverizer which is smaller in size for home use.

High quality plastic pulverizer machine can be used to grind thermoplastic materials such as Low-density polyethylene (LDPE) and ethylene vinyl alcohol (EVA).

Other materials include Polyvinyl Chloride (PVC), Polyester, cross-link, ABS, High-Density Polyethylene (HDPE), polyethylene terephthalate (PET), and Nylon.

When you buy PVC pulverizer, you can also use it to pulverize film waste, sheets, and tubes of soft and hard, impact, and brittle resistant materials.

High-quality pulverizer is easy to clean and maintain and has an economic option. It doesn't consume power and it has a robust design. In fact, time and effort are saved by its ease of operation.

Advantages of High-Quality Plastic Pulverizer machine

v It is easy to install and maintain, you can open the door cover, clean, and replace tool.

v It has a plastic grinder cooling system which is based on wind and water cooling.

v The whole process is fully sealed, with no dust pollution.

v It has a high yield, fine flour, energy conservation, and environmental protection.

v Its applicability is wide and grinding can be PVC, PS, PA, PC, and other plastic

v 10-20 mesh powder size is adjustable and it has convenient adjustment.

v It uses a new cutting tool structure which improves production and strengthens the cutting tool wear resistance.

Conclusion

For your best processing of material and conversion of materials check out the high-quality pulverizer machines.

These machines come in various sizes which can suit both industrial and domestic use.

High quality plastic pulverizer machines can be used to smash, break, and grind items such as bottles, pipes, jugs, and many other items that are reused for other purposes.

The machine has many advantages such as it is easy to clean, maintain, install, and gives accurate sizes when use to smash items.

However, if you desire to buy PVC pulverizer, buying from an experienced and reliable manufacturer is the best way to satisfy your desire.

By continuing to use the site you agree to our privacy policy Terms and Conditions.