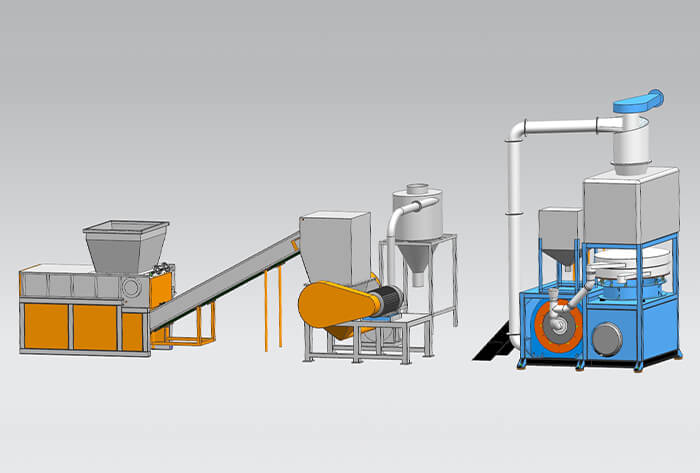

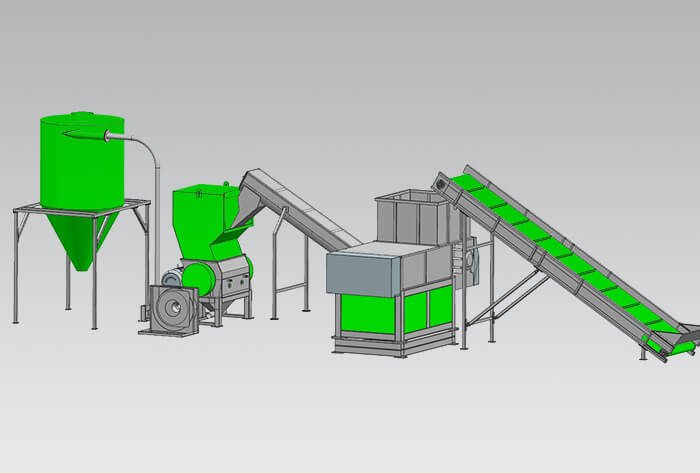

Plastic and rubber products are familiar articles in everyday use. Huibang offers single machines and complete systems for the size reduction of thermoplastics, heat-sensitive materials, plastic waste and rubber.

In the plastic and rubber field, huibang offers a wide range of shredders, granulators, and pulverizers for the size reduction of lumpy materials at high throughput rates, e.g. scraps from blow and injection moulding or extrusion processes, turn them into chips, flakes, granules or even powders.

Machines can be easily integrated into the production process

Customizable to fit specific needs

Wide field of applications, High energy efficiency

Quick and simple maintenance while complying with global safety requirements

Herbal grinding site

Oil pipeline lubricant production line

PE grinding Site

PP powder prodction site

PVC floor crushing & grinding line

XLPE recycling line

Efficient pulverizing systems, grinding mills and disc mills reliably produce high-quality plastic powders for rotational moulding, the production of masterbatch and for coating.

Good flowability

High bulk density

In order to transfer valuable waste materials into reusable materials, Huibang provide machines and systems ranges from the production of coarse and fine powders up to breaking and cutting of basic materials into granules.

HUIBANG supplies solutions for the recycling and preparation of:

For the rubber recycling fields, Huibang supplies shredders, crushers and pulverizers as single components or recycling systems.

The fine rubber powder made from waste tires can replace part of the raw rubber. It’s the method for harmless, resource-based and industrialized treatment of "black pollution". The recycled rubber powder can also be used in the field of :

During the processing of micronized powder in the food and pharmaceutical industry, we hereby always follow the current safety and hygiene regulations, retain the natural characteristics and aroma of raw materials. No matter need the laboratory machine or production equipment, Huibang milling systems can meet your needs.

Huibang offers a wide range of pulverizers for different throughput ranges and applications. The key process parameters including the pulverizer disk geometry, the grinding gap setting, the feed rate of the input material, the temperature in the grinding chamber, and the screen fineness.

The range of pulverizers extends from units for laboratory to the plant pulverizer systems

Various Disc configurations available

Best control of particle size distribution

Special cooling systems for food and pharmaceutical industry

Herbal grinding site

Oil pipeline lubricant production line

PE grinding Site

PP powder prodction site

PVC floor crushing & grinding line

XLPE recycling line

Depending on the requirement, we supply the machines and systems in stainless steel, polished, gas-tight or for suited for cryogenic grinding.

Machines and systems from Huibang are used for diverse tasks:

For size reduction of food products, especially spices, cocoa and coffee, herbs, vegetables and gelatine

For the production of animal feed, dry foods and frozen meet

Capsules are currently the most popular oral solid dosage form in the pharmaceutical industry. Grinding by cryogenic mill machine can not only retain the active ingredients in the medicinal materials, but also produce ultra-fine powder.

We have been developing and manufacturing size reduction machines and complete preparation systems for the wood products and chemical industry.

Huibang size reduction machines for wood and chemisty field such as the turbo type pulverizer machine, crusher machine , integrated into complete systems, provide for constant quality of the granules or powders at high throughput rates.

Energy efficient,Higher production rates

Versatile and space-saving configurations

Different disc configurations to increase output

Herbal grinding site

Oil pipeline lubricant production line

PE grinding Site

PP powder prodction site

PVC floor crushing & grinding line

XLPE recycling line

We have tailored solutions for many requirements:

Biopolymers, Cellulose Derivatives, Dyes & Pigments, Fertilizers, Fibrous Materials, Oily & Fatty Materials, Natural Resins & Pitch and Salts & Phosphates.

Huibang provides effective and reliable machine for reducing fiber size. Precision knife grinding produces fine powder with good mixing and adhesion. After adding fiber powder as an additive to the raw material, the strength of the raw material can be enhanced. Huibang's cryogenic system can produce ultra-fine powder.

Wood: Annual Plants, Paper, Particle Boards, Medium Density Fibers (MDF), Oriented Strand Board (OSB), Waste Wood

WPC: Wood Plastic Composites, Natural Fiber Composites, Cork Plastic Composites and WPC Panels.

Depending on the feed material as well as on the desired throughput rate and the required end fineness, HUIBANG supplies different kinds of crusher and knife mills to produce pre-broken waste wood, wood chips and coarse shavings. These materials can be used as components in particleboards and in the energetic usage as wood pellets for example.

If you have questions about our products, please Email us immediately and we will reply you as soon as possible

By continuing to use the site you agree to our privacy policy Terms and Conditions.