A pulverizer machine are used for grinding various plastic materials into powdered form.

The PE pulverizer serves as a cost-effective and efficient grinder of several thermoplastic materials at standard temperature. This process can also be used as a means of recycling production waste in the plastic industry.

The PE pulverizer is a disc-type plastic pulverizer with a disc diameter of 350 to 800mm. They are accurate grinders for powder processing of hard, medium, friable and impact-resistant plastic materials.

PE pulverizer generates high-quality powders (high bulk density and free-flowing) for use in rotomoulding applications.

The advantages of this pulverizer include high throughput, compact size, high speed, low power consumption, high capacity, and more.

With the productivity and power consumption, PE pulverizer is the most efficient and cost-effective air-cooled mill, and the compact size makes it perfect for processors and producers.

Do you desire a cost-effective and efficient mill grinder? Ensure to buy the PE pulverizer machine from a reputable manufacturer.

How it works

As stated earlier, the PE pulverizer is a disc-type plastic pulverizer machine with a disc diameter of 350-800mm. It is an accurate grinding machine of plastic materials.

The desired material to be ground is introduced via the centre of an uprightly fixed milling disc which is installed concentrically with a matching high-speed spinning disc.

Centrifugal force then conveys the material via the milling area, and the ensuing powder is gathered with a cyclone and blower system.

The pulverizing machine can be supplied with a piece of milling disc or several disc milling segments, depending on the application.

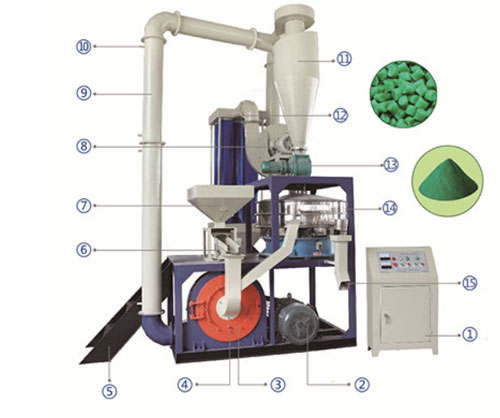

The pulverizer machine has components such as draft fan, cyclone separator, air shutter, vibration sieve, ladder, dust catcher, cooling water intake and outtake, etc.

With the array of optional components, pulverizer machine can be designed based on customers processing requirements and budget.

Procedural Features

· Complete automatic device

Automatic feeding, releasing and sorting.

· Adjustable vibration feeder

The electromagnetic vibration feeder is adjustable, giving stability to the milling chance starting current.

· Milling disc

The various disc configuration designs are of high quality, durable, strong resistance, and longer life span compared to average ones.

· Completely sealed

The entire pulverizing process is sealed, with no dust leakage.

· High rotation rate

The motor ensures fast and efficient milling, which significantly saves the time of operation as well as an engineering control.

· High production efficiency

· Simple and save adjustment of the milling gap

· Low drive power

· Wind and water double cooling system

· Easy to install

· Durable and Reliable

· Convenient maintenance

Areas of Application

Pulverizer machines are used in the following applications:

v Sheet and pipe crushing and recycling

v Composite plastic production

v Rotomolding powder production

v Extruded plastic recycling

v Engineering plastic compounding

v Size reduction of plastics

In case you need to invest in an economical and highly effective pulverizer that gives appropriate output size, the PE pulverizer machine is the ideal equipment for you.

Kindly contact us and you will be glad you invested in the best product from a professional manufacturer.

By continuing to use the site you agree to our privacy policy Terms and Conditions.