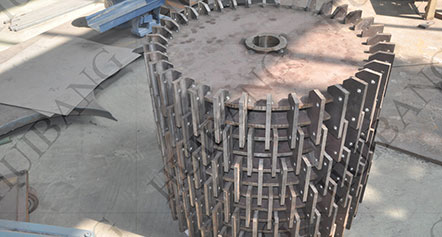

The essential processes of pulverizing happen in the cutting hall of the granulator. The cutting hall also covers the crucial replacement segments of granulators and knives.

The machine uses extra energy to cut when the cutting side of the knife fails. When the edge of the knife failed there will be low and bad regrind quality, and there will not be uniformity in the cutting size.

Mostly what causes granulator blade failure is the wrong selection of blade, when you chose an improper blade it will fail quickly and affect the cutting.

However, to maintain the number of material to be recycled purchasing plastic pulverizer blades from an experienced manufacturer is the most recommended option.

Need to stabilize wear resistance and toughness.

It is necessary to know the right blade to use. In many applications, D2 steel which is hardened up to 59HRC Rockwell is the most time used to produce the knives.

Most importantly, all the stages of granulating are necessary. You need to measure the granulator's blade hardness to improve its output and life span.

The first thing in improving plastic pulverizer blades material is to locate adequate balancing of toughness and wear resistance.

Also, the material to be granulated is not contaminated, and it is also consistent because this only virgin film can enter the granulator. In this process, the plastic pulverizer blades Material will have higher toughness to exploit knife life.

However, the handedness of the blade is not crucial because a result of the material to cut is consistent and thin.

From another angle, large and different materials are granulated, and most times plastic recyclers find staples, bottle caps, labels, and screws among the material, all these can cause the blade edge to damage and causing edges low performance this is when the blade toughness is very high.

Many materials are being processed by a plastic recycler, and these range from easy to thin thick and hard material.

With these various materials, plastic recyclers see it as an easy thing to utilize knives which have lower toughness, and this is done to hold all the types of items or material and avoids damaging the edge for cutting and improve blade life.

Most importantly, it is good to assess the work performance of your plastic pulverizer blades after processing. Search for any damaging edges and sawtooth on the cutting edge.

However, if the edge is damaged means the toughness of the plastic pulverizer blades material is extreme.

To run a check on the edges of your blade, record the sum of material processed within blade changes. If the total of the initially processed materials drop means the plastic pulverizer blades are tiring too soon when you noticed your blades getting blunt quickly that means the knife toughness or hardness is very low.

Do you need good Plastic Pulverizer Blades?

Sourcing good plastic pulverizer blades for your granulating can be tasking and time consuming, but you can rely on us for the best product any time.

Click here to purchase our good plastic pulverizer blades that will give you satisfaction for your money.

By continuing to use the site you agree to our privacy policy Terms and Conditions.