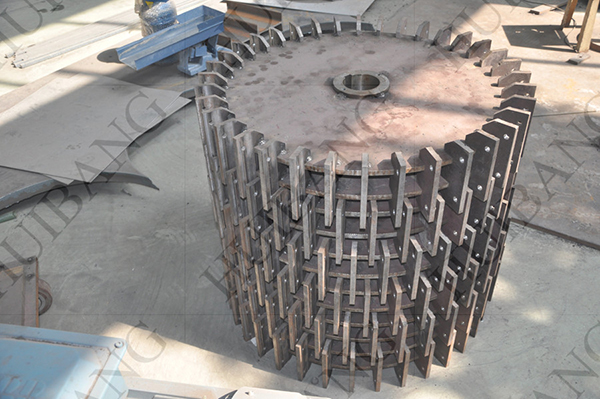

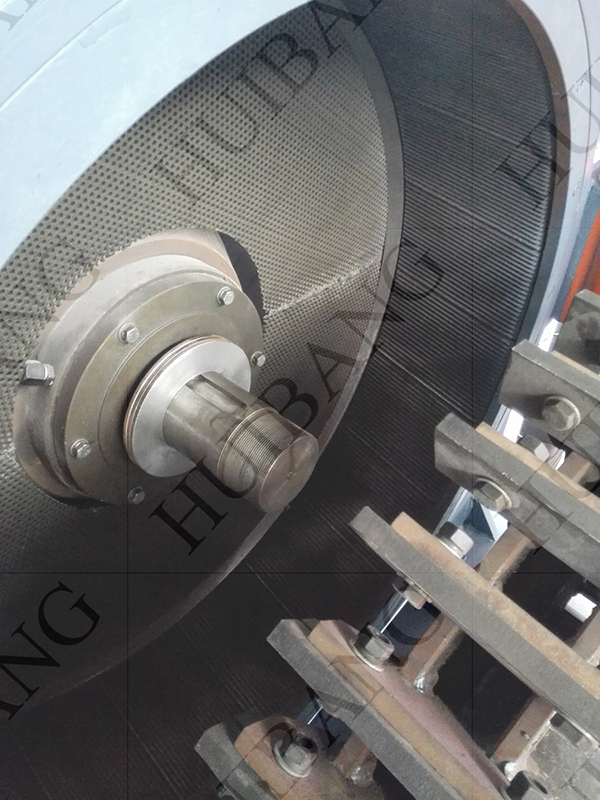

The plastic pulverizer blade is the core component of the PVC pulverizer, its speed is up to 3800 RPM, and bears the impact force. The cutter head is driven by the spindle equipped with precision bearings. Under the drive of the cutter head, the moving cutter rotates at high speed and is tangent to the fixed cutter, so that the material entering the cutter has a strong collision and is ground into powder.

Based on the working environment and principle of PVC pulverizer tool, the processing link and raw material selection are strictly checked, it is suggested that customers in the purchase of plastic pulverizer, must choose high quality tools, so as to make the pulverizer for you to create more value.

In the process of material grinding, the high-speed rotating rotor makes the material moving at high speed collide strongly with the fixed knife and the moving knife, and the powder is formed by friction. Its basic principle is through the wind, water cooling is compatible, control the crushing temperature of the material, the quality of the crushed material will not change, in the configuration of automatic feeding, automatic discharging and automatic sorting system, greatly reduce the labor intensity. The whole grinding process of the machine is completely closed, no dust leakage, refueling cleaning, just open the door cover can be maintained.

In this process, the huge impact force of the knife will pass through the tool rest plate to the two circular plates of the rotor. At this time, if the quality of the fixed knife is not good and the rotor welding is not strong, it is easy to deformation, leading to the breakdown of the fixed knife, the rotor is broken or even scrapped. Therefore, the material and quality of the cutting tools of the plastic pulverizer are very important.

Many consumers expect to buy things at a low price, but this depends on the quality. If the pursuit of a low price is bound to produce quality problems because things must be made at a high cost. Plastic pulverizer tool quality lies in the choice of raw materials, lathe processing, grinding machine, heat treatment and dynamic balance processing and other links must be higher to reach the standard. If in order to save the tool cost and save a few processing links its quality must be greatly reduced, frequent replacement, maintenance is not cost-effective for consumers.

Contact Our Engineer For Quotation- Pulverizer

Please tell us your request as specific as possible, Our engineer will contact you and provide better solution and quotation for you. Do not hesitate to contact us, you will save more time and money.

By continuing to use the site you agree to our privacy policy Terms and Conditions.