The PC series crusher belongs to the basic model of plastic recycling. It is durable and has a wide range of applications. It can crush various waste materials in injection molding and blow molding, as well as soft materials such as plastic bottles and leather. According to the characteristics of the crushed material, different blade configurations can be selected to help optimize the use of the machine. Acoustic hood and fan recovery device can be installed.

PC series plastic crusher is suitable for crushing polystyrene, polypropylene, nylon, engineering plastic and injection. If you change the suitable sieve pore board, adjust the space among the blades and blade type, it can also be used in crushing the waste of various plastic, films, sheet metal and so on

Cleaning and maintenance is simple and fast

Mobile compact design

According to the particularity of crushed materials, the crusher can be equipped with different rotor structures.

This model can be installed with soundproof cover

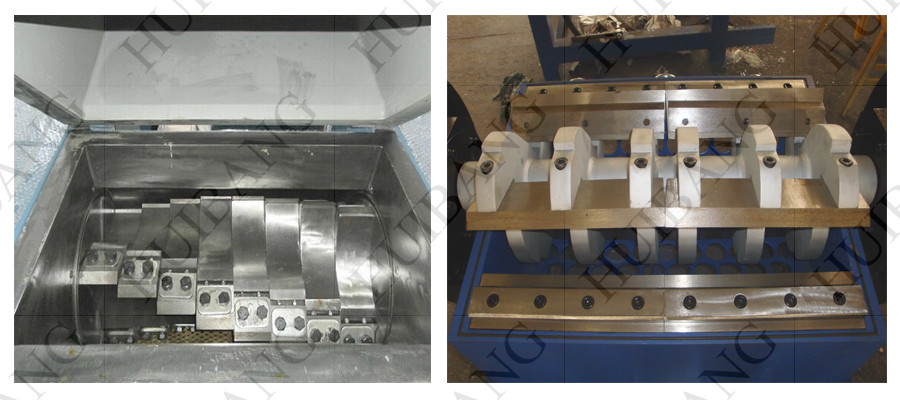

(1) Steel structure tank, cast steel knife rest, holder steel cutters, avoiding crack;

(2) Ladder style cutters, improving the shear force, enhancing crush efficiency; The using life of the alloy blade is much longer than the ( A protective switch is put in the feeding mouth to protect the operator's safety.

(3) Movable screen, dismounting convenience, easy for cleaning and color change;

(4) Sound insulation interlace is used in the feeding mouse to reduce the noise and improve the environment;

(5) Sliding wheel on stand for move easily;

(6) A protective switch is put in the feeding mouth to protect the operator's safety.

Model | PC-400 | PC-500 | PC-600 | PC-800 | PC-1000 |

Crusher Room(mm) | 270*410 | 300*500 | 320*600 | 450*805 | 650*1020 |

Fixed Knife (pcs) | 2 | 2 | 4 | 4 | 4 |

Rotary Knife(pcs) | 12 | 15 | 18 | 24 | 30 |

Main Motor(kw) | 7.5 | 11 | 15 | 22-37 | 45-55 |

Capacity(kg/h) | 200-400 | 400-600 | 500-800 | 800-1000 | 1000-1300 |

By continuing to use the site you agree to our privacy policy Terms and Conditions.