The twin-shaft shredder is mainly used to shred large materials, such as refrigerators and other electrical enclosures, large pipes, pipe fittings, tires, barrels, etc. The machine is automatically controlled by a microcomputer. It is equipped with a start, stop, reverse, and overload automatic reverse control functions. It has the characteristics of low speed, large torque, and low noise.

The two-shaft shredder is a low speed and high torque industrial shredder . This dual shearing shredder does not have a screen unit. After material is fed into the hopper, material is handled using two counter rotating blades, then directly discharged. Although the output particle size is random, the two shaft shredder features a faster shredding speed and a higher throughput than other shredders.

The industrial shredder can be custom tailored to suit your material and requirements to ensure maximum economic and production benefits.

Application Areas:

plastic sheets;

electronic waste;

scrap (components, subassemblies; consumables);

metals(lead, aluminum, copper, cable, barrels, sheet scrap, sheet metal pieces left over from production processes);

aluminum cans;

wood(wooden pallets or fruit boxes);

plastic(plastic bottles or canisters);

waste tire, rubber;

waste household appliances;

paper waste (cardboard, newspaper, office paper, books, magazine, kraft paper, paper core, cardboard tube, paper packaging material);

textiles (rags, garments, carpet);

animal bones and organic waste.

Rotor/Drive train

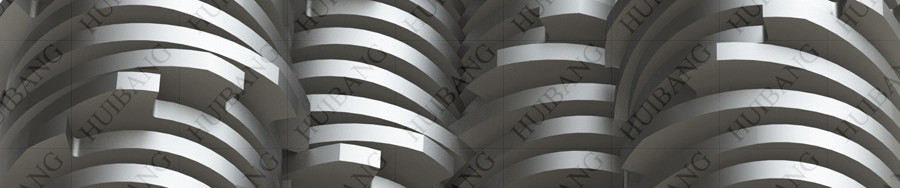

Rotors: “V” arrangement cutter blades create a uniform shredding force. Blade material and structure: CrMoV superior alloy steel. A variety of materials and configurations are also available based on your application demands. The double sided walls are made of a wear-resistant steel plate, ensuring a high abrasion resistance and excellent durability.It incorporates two counter-rotating shafts that intermesh with each other(2 shafts with sharp elements constituted by sharp-corners disks provided with hooks); Every hook has the task to hook the product and drive-it by the action of the two counter-rotating shafts). The material is powerfully torn and shredded by the talons of the cuttings discs. Specially designed rotor makes the shredder be extremely wear resistant.

Drive train

A motor and hydraulic drive are provided to meet different applications. Hydraulic ram: common two shaft shredders don’t come with a hydraulic ram. HUIBANG can add a hydraulic processing ram according to special material handling requirements, allowing customers to improve their output.

Double Shaft Shredder Blades(According to different materials choose different blades ):

Technical Features:

1. MCT series shredders can be employed as either a primary or secondary shredder and can be seen working anywhere from the waste management company to biofuel producers;

2. Dual shafted, slow-speed, high-torque waste shredder with hardened steel cutters;

3. The two cutting rotors powerfully grab the feed material, and no matter the feed material is large piece of hard plastic or heavy tires, this machine can easily shred them into small pieces;

4. Double shaft shredder is able to process a number of different materials; shredder is designed with a powerful engine, long working length and aggressive input, Internal feeding volume bigger than traditional and common single shaft shredder machine and allow you using forklift truck to feed.

5. Heavy structure: the frame and structure of our shredders are made of high-thickness sheets and tubular. Blades are manufactured from high quality steel, suitable for shredding tough materials and for extra long life;

6. Depending on requirement, these discs (blades) are available in a wide range of quantities, qualities and shapes with the new double-shaft shredder;

7. Any overloads caused by foreign material are sensed by the PLC controller and cause the shaft rotation to stop and reverse direction to clear the foreign matter, and then resume;

8.Cutters removal and replacement can be carried out safely and simply.

9. Our shredders Use a planetary reducer, not a traditional gearbox, and the planetary gearbox has the following advantages: High Efficiency, Greater Stability, Compact Size, Higher Torque Density, Cost Effective Precision, High Radial Loads.

10. Cooler system(optional) can maintain the temperature for continuous operation.

The normal package is wooden box.If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

By continuing to use the site you agree to our privacy policy Terms and Conditions.